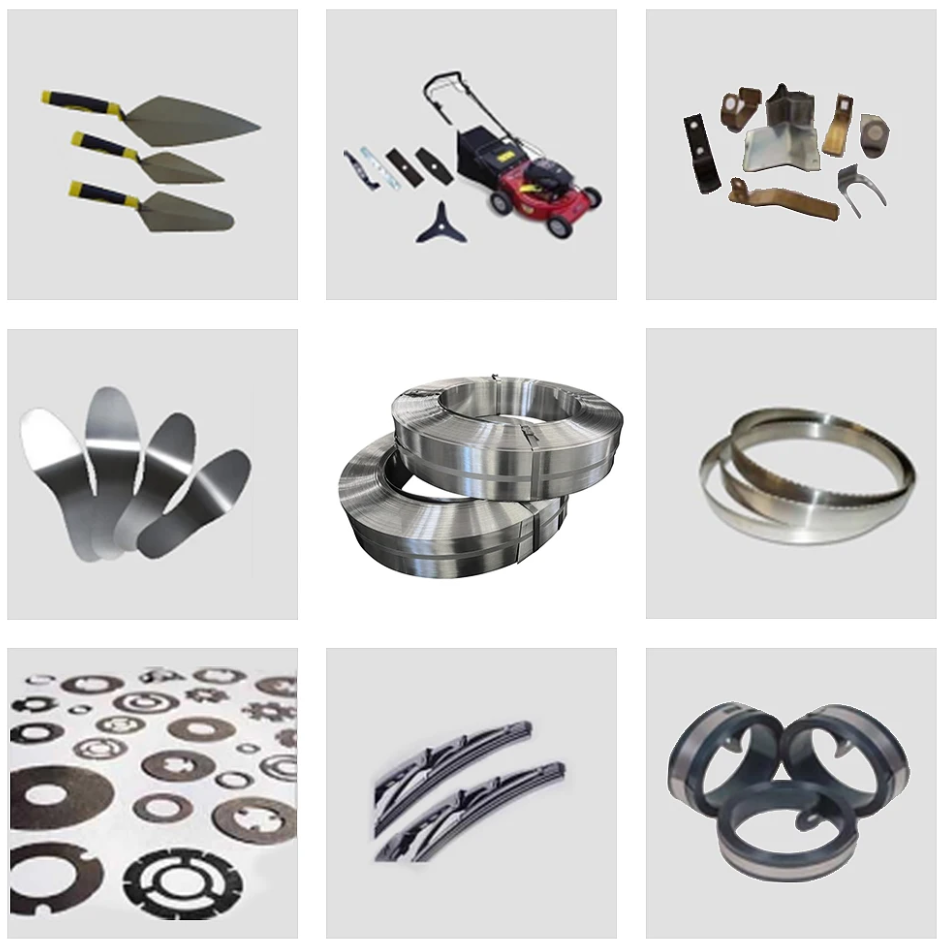

Why Steel Strips Matter

From automotive manufacturing to household appliances, steel strips—thin, flat-rolled sheets of steel—are everywhere. Their versatility, strength, and cost-effectiveness make them indispensable in modern production.

Key Features & Applications

Durability Meets Flexibility

Steel strips withstand extreme temperatures and pressure, ideal for automotive parts (e.g., seat belts, springs) and construction frameworks.

Thin yet robust, they’re easily shaped for precision tools, electronics, and packaging (think canned goods!).

Sustainability Champion

Recyclable and long-lasting, steel strips reduce waste and energy consumption. Over 90% of steel is reused globally.

Innovation in Action

Advanced coatings (zinc, polymer) prevent rust, extending product lifespans.

Ultra-thin strips (<0.1mm) now power miniaturized tech, like smartphone components.

Choosing the Right Steel Strip

Grades: Pick carbon steel for strength or stainless steel for corrosion resistance.

Thickness: Match to your project’s load requirements (e.g., 0.2mm for electronics vs. 3mm for machinery).

Surface Finish: Opt for polished strips for aesthetics or matte finishes for industrial use.

Join the Conversation

How have steel strips impacted your work? Share your insights below!